Context and challenges

The environmental quality approach for a building, initiated 20 years ago by players in the construction sector, is currently going through an important phase of transition towards environmental performance. The law on energy transition also promotes the notion of high environmental performance. This involves three major changes:

- From energy to environmental impacts: positive energy building, low carbon, resource-efficient, recyclable, low-polluting…, environmental performance covers all these issues in a coherent way and ensures that pollution is not transferred.

- From the use phase of the building to all the phases of their life cycle: on energy, for example, a life cycle approach means that all energy consumption is taken into account: the embodied energy of products and equipment of the construction but also all the consumption of the use phase, beyond the consumption subject to thermal regulations, as well as those of the construction and deconstruction phases at the end of the life of the building

- From the evaluation of the means to that of the results: thanks to the Life Cycle Analysis, the scientific evaluation of the results of the action strategies adopted is made possible thanks to a set of quantified indicators (tons of CO2, liters of water…)

Article 181 of the Elan law (2018) indicates that from 2020 for all new constructions, a level of carbon footprint must be respected according to each type of building. This assessment is carried out over the entire life cycle of the building. This is a first step for the larger scale use of ACV.

Definition

Life cycle analysis is the most advanced tool for global and multi-criteria assessment of environmental impacts. This standardized method makes it possible to measure the quantifiable effects of products or services on the environment.

LCA identifies and quantifies, throughout the life of products, the physical flows of matter and energy associated with human activities. It assesses the potential impacts and then interprets the results obtained according to its initial objectives. Its robustness is based on a dual approach:

A “life cycle” approach

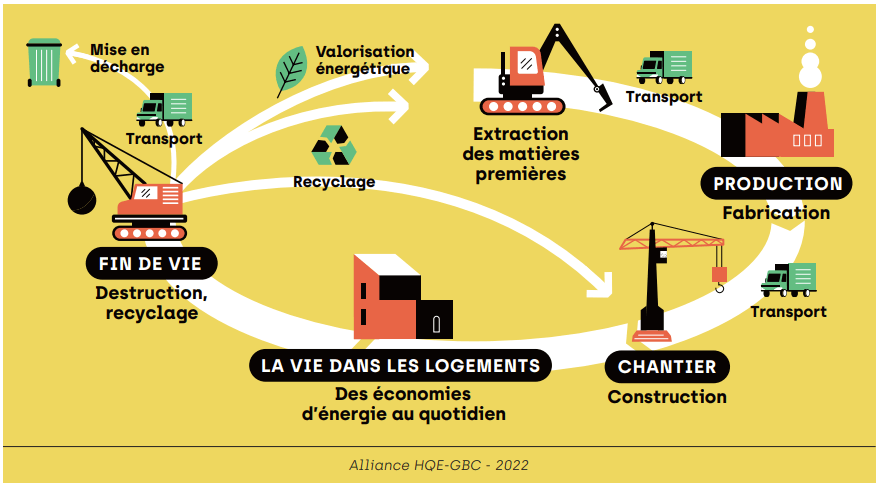

Whether it is a good, a service, or even a process, all stages of the life cycle are taken into account for the flow inventory, “from the cradle to the grave”: extraction of energy and non-energy raw materials necessary for the manufacture of the product, distribution, phases of use and maintenance, collection and disposal towards end-of-life channels (recycling, landfilling, etc.) as well as all phases of transport.

A “multi-criteria” approach

An LCA is based on several criteria for analyzing incoming and outgoing flows. The incoming flows mainly represent the components needed to manufacture the service, including energy, the outgoing flows corresponding more to the notions of waste, pollution, gaseous or liquid emissions, etc. Each flow is quantified, for each stage of the cycle, and corresponds indicators of potential impacts on the environment. The complexity of the phenomena involved and their interactions generates uncertainty about the real value of the impacts, which is why they are called “potential”.

LCA is a standardized evaluation method, developed by international standardization from the 1990s in the ISO 14040 to 14044 standards. The methodology has thus been harmonised, bringing more robustness and reliability to the results, by formalizing the communication (requirement of a critical review for comparative LCAs). LCA is therefore a procedure, a series of standardized steps, constructed as a mathematical model of transformations making it possible to match flows with their environmental impacts.

The work of the Alliance HQE-GBC

LCA and RE2020

In 2022, RE2020 comes into force. Realization of the National Low Carbon Strategy for the construction sector and culmination of the E+C- experiment, it requires building stakeholders to master the Life Cycle Analysis which is now becoming regulatory for a certain number of structures. . In order to support the actors of the sector in their necessary adaptation to this new regulatory situation, the Alliance HQE-GBC publishes the Guide on the wealth of LCA. This guide has two main purposes:- continue the acculturation of professionals in the sector to this tool

- promote its multi-criteria aspect, i.e. the consideration of environmental impacts beyond the requirements on greenhouse gas emissions of RE2020.

New LCA – E+C-

In 2016, the State launched an experiment for the new building regulations, which combines energy and the impact of carbon: this is the E+C- experiment: positive energy and carbon reduction. The Alliance HQE-GBC contributes through its HQE Performance collaborative work to this dynamic. The methodology used for HQE Performance is that of the E+C- experiment. The carbon impact is included in the environmental performance of buildings. It is based on reducing the environmental impact of the building throughout its life cycle (from the production of components to its end of life). This assessment is based on the LCA principle and the NF EN 15978 standard. The HQE-GBC Alliance also monitors various works at European and international level on this dynamic. In order to inform its members, a working group called GT Environmental Indicators monitors these various projects and exchanges these practices.

LCA Renovation

On the LCA renovation side, it was in 2017 that the Alliance HQE-GBC launched an HQE Performance test for existing buildings in order to provide a methodological framework, based on the EN 15978 standard, adapted to this type of building: buildings renovated, whatever the ambition of the renovation in the form of an Addendum to the E+C- standard for renovated buildings. This work has made it possible to define, for a world first, a method for the LCA of renovated buildings valid for all types of renovation. LCA building renovation can be used for:

- Decision support, to choose between renovation or demolition/reconstruction;

- The optimization of a renovation by choosing between several types of renovation;

- The environmental assessment of a building stock comprising both new buildings and existing buildings to be renovated.

The application rules for evaluating the environmental performance of existing buildings are a continuation of the evaluation method of the “Energy – Carbon” benchmark, itself based on standard NF EN 15978. In this method, the impacts environmental impacts of construction products and equipment over their life cycle are not instantaneous or phased, but are smoothed over the entire life of the products and equipment, producing a damping effect. With a linear hypothesis, if a product has a lifespan of X years, each year 1/X times its environmental impact will be amortized over the “total life cycle”. This is an accounting view of the LCA: if the products and equipment installed in the initial building have already been depreciated over the study period taken into account in the life cycle analysis (fictitious or not) of this building initial, they should no longer be counted. Thus, the impacts related to products and equipment retained and removed during a rehabilitation operation are only recognized if they are not amortized. The environmental impacts of new PCEs and refrigerants are calculated as in the case of a new building, 100% of the impacts.

LCA Products – FDES and PEP

To eco-design buildings and assess environmental performance over their life cycle, it is necessary to know the environmental performance of products, equipment, and services. Two prerequisites are required:

- environmental performance must be evaluated in the same way by everyone in order to aggregate consistent data. This is the whole point of the INIES admission rules, which are based on standards and supplement them, if necessary;

- a digital data format to feed LCA Building software.

The INIES database, owned by Alliance HQE-GBC, meets this need by bringing together Environmental and Health Declaration Sheets (FDES) for construction products and Product Environmental Profiles (PEP) for building equipment as well as values by default and conventional service data made available by the State. The FDES are provided by manufacturers, professional associations, technical centres, etc. They are established in the format of the European standard NF EN 15804+A1 and its national supplement NF EN 15804/CN for construction products since July 1, 2014. For building equipment, PEP ecopassport® are based on standard NF XP C08-100-1 and PCR ed3. These standards set the methodology for assessing the environmental impact indicators of construction products and equipment: energy consumption, global warming, resource consumption, production of final waste, water and air pollution, etc. Completing such a declaration implies having a life cycle analysis (LCA) of the product or equipment, together with health information resulting from specific tests for FDES. All these sheets are verified by independent third parties (Type III declaration – ISO 14025).